So, I simply couldn't resist it. I wanted to see if the LimeSDR mini would work as well as it seemed to with my bench tests and I'd been purchasing a few LNB's to play with as well.

Now how could I test it ?

Firstly I needed a Bias Tee - I could of course buy one but that would take time (and money!) - I had all the bits so why not make one there very simple. I even found a nice Maplin box to put it in - remember Maplin ? - So after a very pleasant 90 minutes - most of which was actually drilling and fitting the PCB into the box and printing some labels to ensure that I didn't apply voltage to the LimeSdr Mini in my haste, thus it was complete, labelled and tested.

Next was a dish

Now I plan to buy a 1M or 1.2M offset dish but I haven't got round to it....

Cue my daughter who last weekend got Sky Q fitted to her home, and happened to mention that they replaced the 'old' dish with a new one and have left the old one - so I hot footed it around to her house to take possession - result.

After much derision form the better half along the lines of 'what are you doing with that rusty piece of junk?' - I had a zone 1 (45cm ?) sky dish which whilst on the really low edge of size would hopefully enable a proof of concept for reception of the narrow band transponder.

I wasn't going to mount the dish permanently so I used a tripod that I have for small beams when I go out portable for the low power Practical Wireless 70Mhz contest (I won it one year!)

I had a cranked mounting bracket (courtesy of a next door neighbour that was going to throw it out sometime ago) - and so I was set.

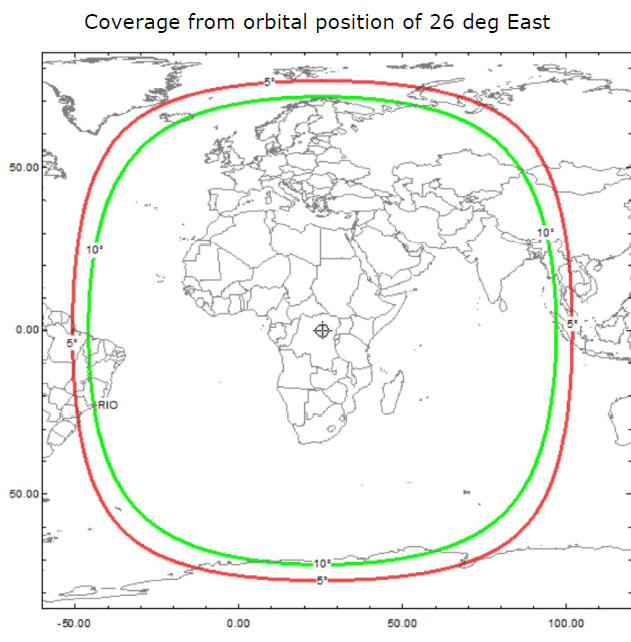

Our house faces south and so it was simple to get the dish mounted and pointing in the right direction, I set it for the right elevation and direction using dishpointer on the web and my phone. Connected up the cheapest LNB (always good to have a challenge). Then connected that to the newly built Bias Tee, which then connected to the LimeSDR Mini and then of course that was connected to the computer via a USB 3 connector, then centred the tuning on 740Mhz.

Our house faces south and so it was simple to get the dish mounted and pointing in the right direction, I set it for the right elevation and direction using dishpointer on the web and my phone. Connected up the cheapest LNB (always good to have a challenge). Then connected that to the newly built Bias Tee, which then connected to the LimeSDR Mini and then of course that was connected to the computer via a USB 3 connector, then centred the tuning on 740Mhz.

Did it work ? Well the short answer is yes and first time to my very great surprise !

I could see and hear the CW Beacon and the data Beacon at either side of the waterfall and I could even see some signals in between them !

I haven't optimised LimeSDR Mini for gain or anything just using it pretty much straight 'out of the box' - excellent results

You can see on the left hand side the CW Beacon and on the right hand side the data beacon with signals in between ! - and this was without tuning the dish and with a sub optimal one at that - amazing !!!! - Might not be up to the BATC Narrow Band monitor but then that's at goonhilly quite a lot further south and also with a 'proper' size dish and a locked LNB !!!!

Here are two recordings (apologies for the quality, not recorded directly but via an iphone!) of the CW Beacon and DH2PA calling CQ through the satellite.

I used the low cost (£7) single output LNB - I opened it up and it does have a pll with a 25mhz Crystal - and the stability after a short period was very acceptable - you can hear a slight warble on the CW recording, also I noticed that the frequency was a little low, but plan to use a GPS locked signal which should help to resolve that!

I then used a more expensive (£13.00) dual output LNB - this again is a PLL one, this also worked just as well (no better than I could tell from this subjective not quantitative test!)

Low Cost PLL LNB Higher Cost PLL LNB

The cheap one was from eBay and the more expensive one was from Amazon, I also have a classic Octogon quad output to test as per my previous post.

Now to go an order the 1M dish and make things a little more permanent, i've started work on a dual feed already so I should only need one dish / antenna.

Not bad for a £7 LNB, a free dish, and a little work to make a bias T - admittedly the LimeSDR Mini did cost me just over £100 but that also includes a transmitter as well!!

Trying to cover all the bases I ordered a dual feed from AMSAT-DL sometime ago (several weeks) and forgot about it.

Trying to cover all the bases I ordered a dual feed from AMSAT-DL sometime ago (several weeks) and forgot about it.